Aluminum is one of the most widely used metals in modern fabrication. Its combination of lightweight strength, corrosion resistance, and versatility has made it essential across industries such as aerospace, automotive, marine, and construction. Despite these advantages, aluminum can be one of the most challenging materials to weld successfully. Among the difficulties welders often face, cracking is one of the most common and costly issues. A single crack can compromise not only the strength of the weld but also the integrity of an entire structure, which makes prevention a top priority for professionals and fabricators alike.

The reasons aluminum welds develop cracks are rooted in the unique properties of the material. Because aluminum has a very high thermal conductivity, it pulls heat away from the weld zone much faster than steel. This uneven heating and cooling creates stresses that can easily lead to cracking if not managed properly. The thin oxide layer that forms naturally on the surface of aluminum poses another challenge. This oxide melts at a much higher temperature than the base metal, and if it is not removed before welding, it can cause contamination and weaken the weld. Certain alloys are also more susceptible than others. For example, alloys in the 2xxx and 7xxx series are notoriously prone to hot cracking during welding. On top of this, poor technique, improper filler selection, or inadequate shielding gas can further increase the risk.

There are several types of cracking that may appear in aluminum welds. Hot cracking, also called solidification cracking, occurs while the weld metal is cooling and shrinking. This is especially common in alloys with a wide solidification range or in joints that do not allow for shrinkage movement. Cold cracking happens after the weld has cooled, often as a result of hydrogen trapped in the weld or residual stress from improper procedures. Stress cracking may develop over time if a weld is poorly executed and subjected to continuous strain in service. Understanding these differences is important because each type of crack has different root causes and therefore requires a specific approach to prevention.

Avoiding cracks begins with preparation. The right choice of filler metal is critical, as it must complement the base alloy in order to create a stable joint. Different alloys respond differently to specific fillers, and using the wrong combination can set the stage for failure. Cleaning is equally vital. Aluminum must be thoroughly brushed or chemically cleaned before welding to remove the oxide layer and eliminate contaminants such as oil, grease, or moisture. Even a small amount of hydrogen from contamination can lead to porosity and cracking inside the weld.

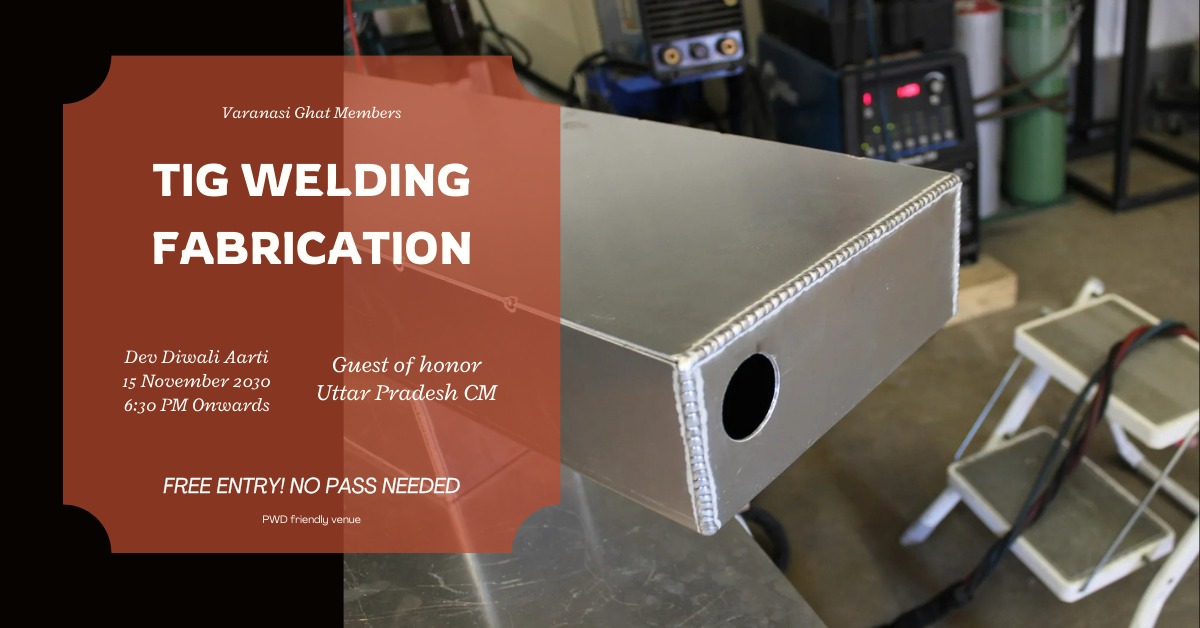

During the welding process itself, heat input needs to be carefully controlled. Too much heat can make the weld more prone to cracking, while too little can leave the joint weak and poorly fused. For thin aluminum sections, TIG welding provides excellent control, while MIG welding may be more efficient for thicker workpieces. Joint design also plays a significant role. Welds that are highly restrained leave little room for the metal to shrink as it solidifies, which can cause cracks to form. Designing joints with proper allowances helps reduce stress and improve overall weld quality.

In some cases, preheating aluminum can make a big difference. Preheating thick sections to around 150 to 200 degrees Fahrenheit helps reduce the temperature difference between the weld zone and the rest of the material, which lowers the risk of cracking. Care must be taken not to overheat, however, as aluminum can lose strength if exposed to excessive preheat. Shielding gas is another factor. Pure argon is most commonly used, but for thicker sections, a blend of argon and helium may improve penetration and reduce the chance of defects. Consistent gas coverage is essential to protect the weld pool from contamination.

Once the weld is complete, inspection and post-weld practices also matter. Careful visual checks can catch surface cracks, while non-destructive testing methods such as dye penetrant inspection can reveal flaws that may not be visible to the eye. In highly critical applications, stress relief treatments or controlled cooling processes may be employed to ensure the long-term durability of the joint.

Aluminum is without question a demanding material to weld, but its advantages make it worth the effort. By paying close attention to preparation, process control, filler selection, and joint design, welders can avoid the frustration of cracked welds and instead produce durable, reliable results. At Performance Aluminum Fabrication, our team of certified professionals specializes in aluminum welding and fabrication services. With a combination of expertise, state-of-the-art equipment, and industry best practices, we deliver welds that meet the highest standards of strength, reliability, and safety.