Welding aluminum pipe is a unique challenge that requires a different approach than welding steel. Due to aluminum’s unique properties—its low melting point, high thermal conductivity, and stubborn oxide layer—the line between a perfect weld and a common mistake is very thin.

Achieving Perfect Welds

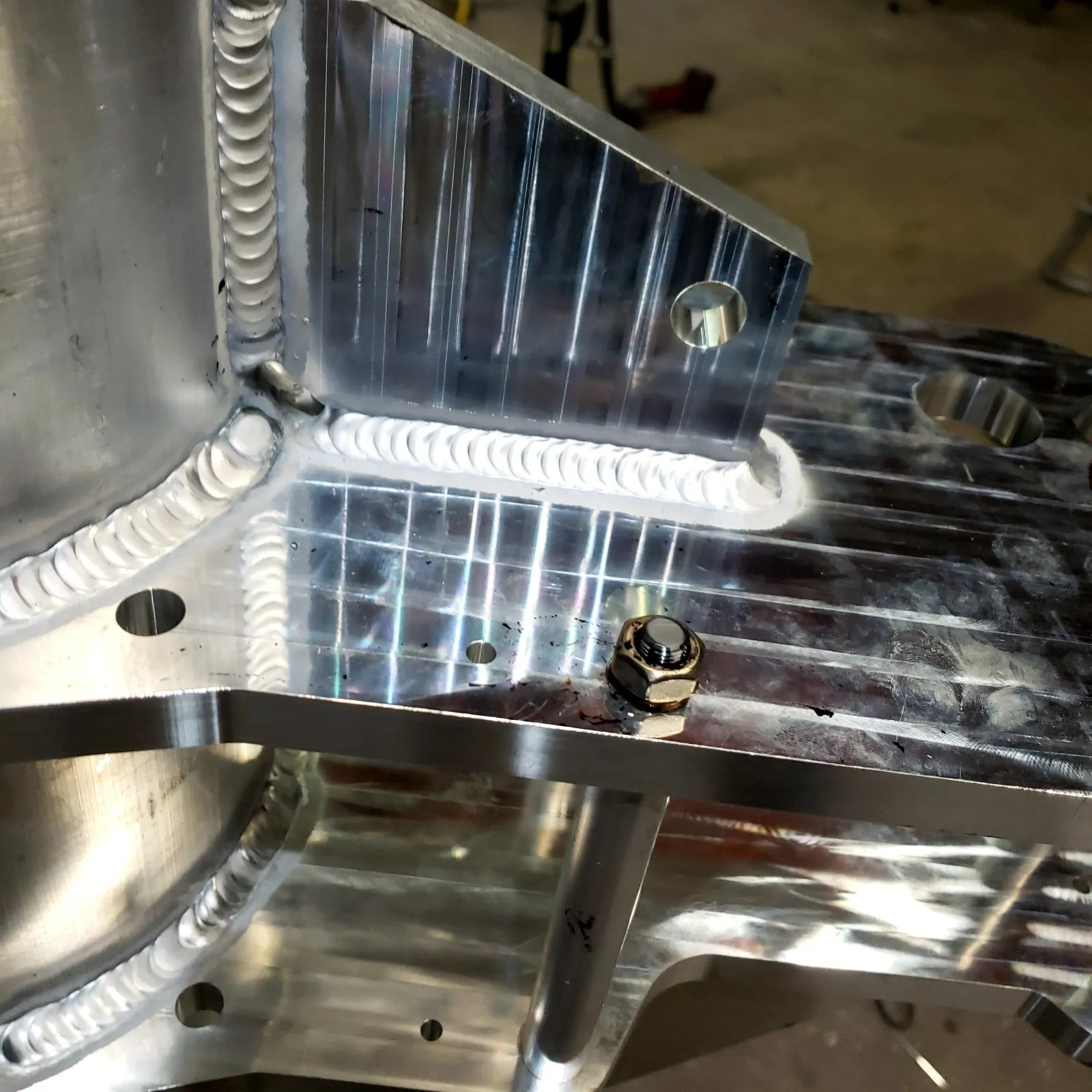

A flawless aluminum weld isn’t just a matter of skill; it’s a testament to meticulous preparation and a masterful technique. When you look at a perfect aluminum weld, you’ll see a consistent, uniform bead with no signs of porosity or cracking. Here’s how you get there:

1. The Foundation: Meticulous Preparation

The single most critical step is proper preparation. Aluminum naturally forms a tough oxide layer that melts at a much higher temperature (3,700°F) than the base metal (1,221°F). This layer must be removed.

- Cleanliness is Non-Negotiable: Begin with a degreaser like acetone to remove all oils, grease, and other contaminants.

- Oxide Removal: Use a dedicated stainless steel wire brush to physically remove the oxide layer right before welding. Using a brush that has touched other metals can contaminate the weld.

- Preheating: For thicker pipe, preheating the joint to about 230°F (110°C) is essential. This prevents weld cracking and ensures the weld metal properly fuses with the base material. Use a temperature indicator to avoid overheating.

Mastering the TIG Technique

Tungsten Inert Gas (TIG) welding is the preferred method for aluminum pipe due to its precision and control.

Tungsten Selection: Choose a pure or ceriated tungsten electrode and grind it to a point. On AC welding, the tip will naturally “ball” slightly, but a precise point provides a more focused arc.

Even experienced welders can encounter issues with aluminum. Understanding the common pitfalls is key to avoiding them.

Porosity

Porosity appears as tiny holes or bubbles in the weld bead and is one of the most frustrating defects.

- Cause: This is typically caused by trapped gases, especially hydrogen, which is absorbed by the molten aluminum and released as it solidifies. The most common culprits are moisture, oils, and grease on the metal surface or filler rod.

- Solution: Ensure the workpiece and filler rod are meticulously clean and dry. Check your shielding gas flow to prevent atmospheric contamination.

Cracking

Weld cracking, particularly “hot cracking,” happens when the weld cools and contracts too quickly.

- Cause: This is often related to improper preheating, using the wrong filler metal, or having too much restraint on the joint, which prevents the metal from contracting naturally.

- Solution: Always preheat thicker materials. Use a filler metal with a melting point similar to the base metal, like a 4XXX or 5XXX series, which are designed for crack resistance. Also, use proper joint restraint to manage the cooling process.

Burn-Through and Lack of Fusion

These are two opposite but equally detrimental heat-related problems.

- Burn-Through: This occurs when too much heat is applied, causing the molten aluminum to collapse and form a hole. It’s a common mistake with thin-walled pipe.

- Lack of Fusion: This happens when the weld metal doesn’t properly melt and fuse with the base material, resulting in a weak joint.

- Solution: For burn-through, use a faster travel speed or a lower amperage setting. For lack of fusion, increase the amperage or slow your travel speed. The key is finding the right balance for a “hot and fast” approach to welding aluminum.

Improper Filler Metal and Technique

Using the wrong filler or technique can lead to a host of problems.

- Cause: Using a contaminated filler rod or applying the wrong welding motion (weaving instead of a straight bead) can introduce defects.

- Solution: Always use a clean filler rod. In TIG welding, “dabbing” the filler rod into the puddle with a smooth, consistent motion is essential. Avoid weaving, which can increase the heat-affected zone and introduce more defects.

Mastering aluminum pipe welding is a rewarding skill. By understanding the material’s unique properties and avoiding these common mistakes, you can achieve perfect, strong, and beautiful welds every time.