For any professional welder or fabricator, selecting the right equipment is the foundation of quality work. When it comes to aluminum, this choice becomes even more critical due to its unique physical properties. Unlike steel, aluminum is a fickle metal that requires specialized tools to achieve strong, clean, and reliable welds. This guide is designed to help you navigate the essential equipment choices, ensuring you are prepared for any aluminum project.

Why Aluminum Requires Specialized Welding Equipment

Aluminum is a highly desirable material, valued for its exceptional strength-to-weight ratio and natural corrosion resistance, but its tenacious oxide layer and high thermal conductivity present significant welding challenges.

Understanding Aluminum Welding Needs

Aluminum’s high thermal conductivity demands higher amperage and duty cycle, its oxide layer requires AC current, and its lightweight nature necessitates specialized wire feeders. The type of work you do—from thin sheets for custom enclosures to thick plates for structural frames—will determine your equipment needs.

Welding Processes for Aluminum

TIG (GTAW) is the gold standard for aluminum, providing the most control for high-quality, aesthetically pleasing welds on thin materials. MIG (GMAW) is a faster, more productive process for aluminum, best suited for thicker materials and long, continuous welds. The Stick (SMAW) process is not widely used for aluminum due to the difficulty of maintaining a stable arc and high risk of poor-quality welds.

Choosing the Right Welding Machine

An AC machine is non-negotiable for TIG welding aluminum because it effectively cleans the oxide layer. A machine with a robust duty cycle is crucial for aluminum to handle the higher amperage required to prevent overheating. Pulse welding technology helps control heat input, reducing the chances of burn-through and distortion. Your choice depends on whether you need a portable machine for fieldworkor a heavy-duty, shop machine for continuous use.

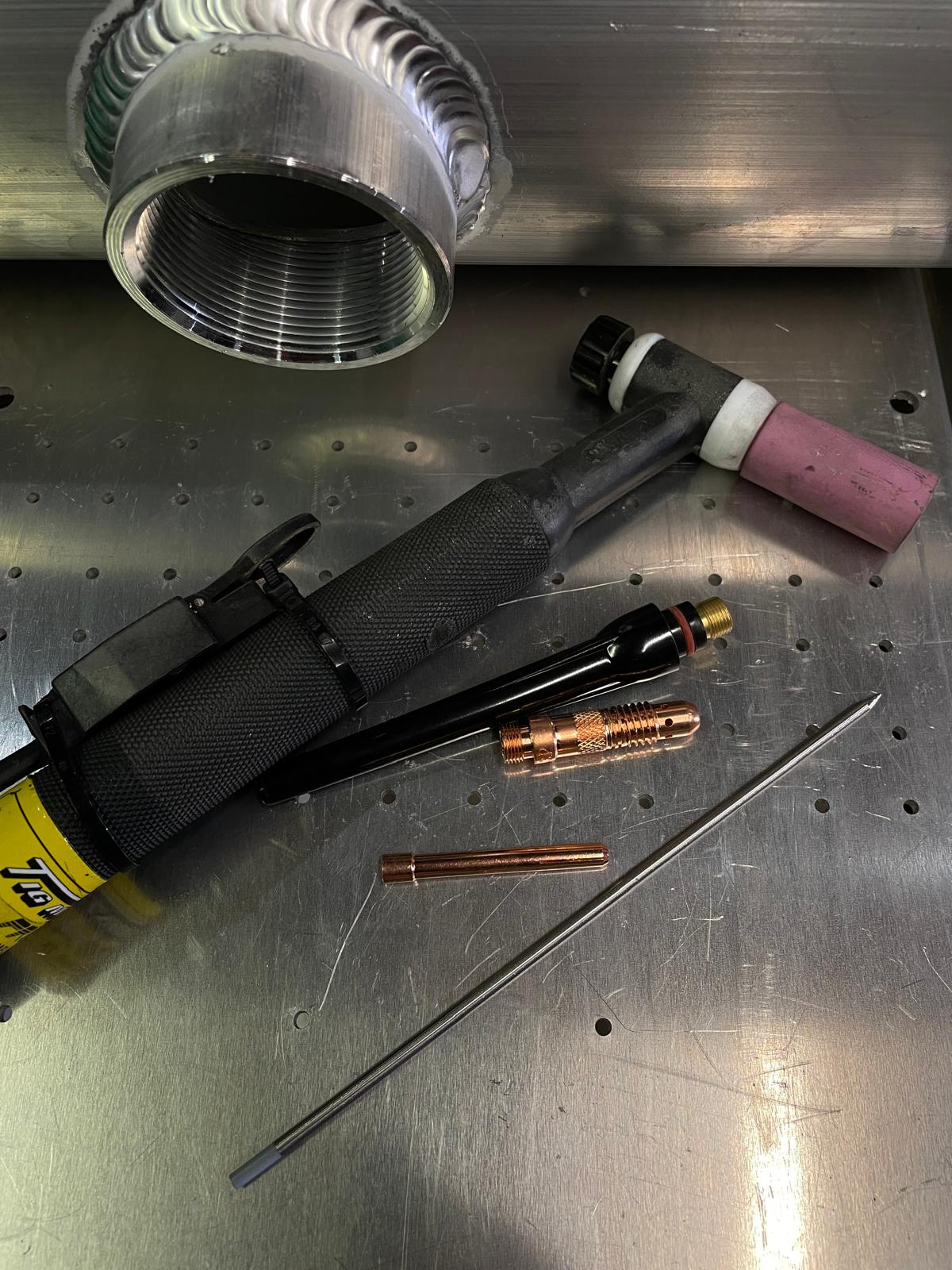

Essential Accessories and Tools

TIG torches are air-cooled for light work and water-cooled for high-amperage, while MIG requires a spool or push-pull gun to prevent the soft aluminum wire from kinking. A dedicated spool gun or a specialized wire feeder with a U-groove drive roll is a must for aluminum. 100% Argon is standard for shielding, while an argon/helium mix can be used for thicker aluminum. The most common filler metals are 4043 and 5356; choose based on the base metal alloy and required properties.

Power Source and Controls

Inverter-based machines are preferred for their superior control and portability. Modern TIG welders offer advanced AC waveform controls to fine-tune the arc characteristics. Digital controls provide greater precision and the ability to save settings for repetitive work.

Safety and Supporting Equipment

A quality helmet, gloves, and protective clothing are non-negotiable for safe welding. Proper ventilation is vital for any shop to mitigate hazardous fumes produced from welding aluminum. A water cooling system is necessary for high-amperage TIG welding to prevent the torch from overheating.

Budget vs. Professional Gear

Simpler machines are suitable for hobbyists or occasional light fabrication work. An investment in professional-grade equipment is crucial for a shop to handle a wide range of projects with greater reliability and quality. The added cost for advanced features, a higher duty cycle, and better controls pays off in increased efficiency and a superior final product.

Maintenance and Longevity of Equipment

Routine cleaning and care of your machine is important. Regularly replace consumables like tips and nozzles to ensure peak performance. Keep modern digital machines updated with the latest software for optimal functionality.