Aluminum Welding Processes: A Welder’s Guide

Introduction to Aluminum Welding

Aluminum is lightweight, strong, and corrosion resistant, making it essential in industries from aerospace to automotive. But unlike steel, it conducts heat quickly, melts at a lower temperature, and has a stubborn oxide layer. These factors make it tricky to weld. Understanding the right welding process, current, and preparation steps is critical to producing clean, crack-free welds. Welders who master aluminum techniques can handle projects that demand both precision and strength.

AC / Power for Aluminum Welding

Power settings play a critical role in aluminum welding, and alternating current (AC) is almost always the preferred choice. Aluminum naturally forms a tough oxide layer that melts at a much higher temperature than the base metal. AC current alternates between electrode negative (for penetration) and electrode positive (for cleaning), giving welders both fusion and oxide removal in one cycle. This “cleaning action” is what makes AC so effective for TIG and MIG welding.Modern welding machines allow adjustment of AC balance, letting welders fine-tune how much time is spent on cleaning versus penetration. This level of control improves weld quality and minimizes defects. While direct current (DC) can be used in rare cases, it lacks the cleaning ability required for most aluminum work, making AC the standard power setting across industries.

Types of Aluminum Welding

GTAW / TIG Welding

Gas Tungsten Arc Welding (GTAW), more commonly known as TIG welding, is the method of choice when precision and control are required. It uses a non-consumable tungsten electrode and a filler rod to create clean, high-quality welds. TIG is especially effective for thin aluminum sections, aerospace parts, and projects where appearance matters, since it produces smooth, defect-free beads. Though slower and more skill-dependent than other methods, TIG offers unmatched accuracy and is widely used in critical aluminum fabrication.

GMAW / MIG Welding

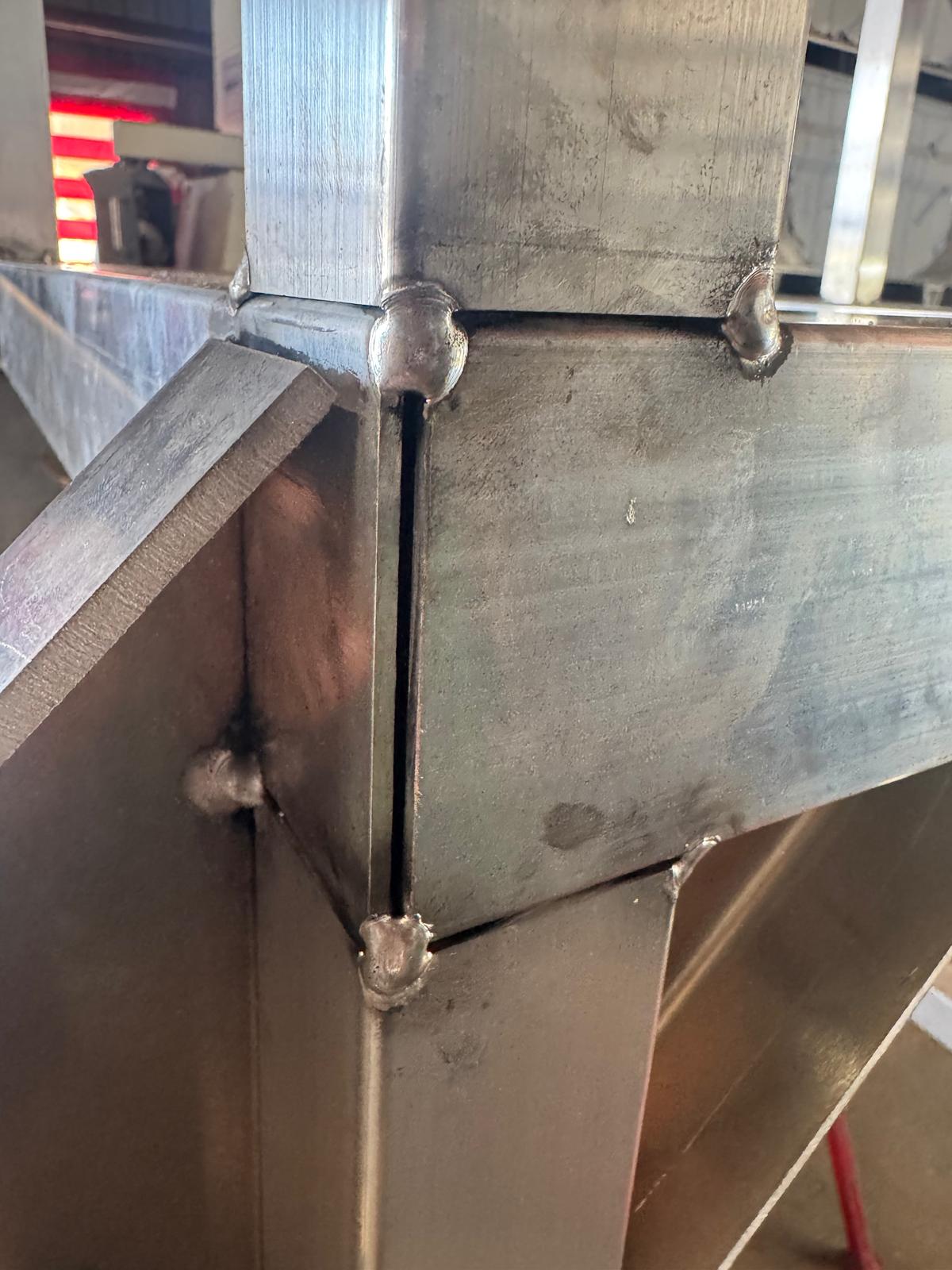

Gas Metal Arc Welding (GMAW), or MIG welding, is preferred when speed and efficiency are more important than fine detail. It uses a continuously fed wire electrode, making it faster and more productive for thicker aluminum and large-scale fabrication. With the right equipment, such as spool guns or push-pull systems, MIG can deliver strong, reliable welds with less operator effort. MIG welding is common in automotive, construction, and industrial applications where productivity and strength are top priorities.

Aluminum Welding Guns, Torches, and Setup

The right gun or torch setup is essential for successful aluminum welding. In TIG welding, welders use a torch with a non-consumable tungsten electrode. For aluminum, a balled tungsten tip with AC current is common, and a gas lens helps deliver smooth, consistent shielding gas coverage. Proper torch angle and electrode extension are critical to avoid contamination and maintain a stable arc.

In MIG welding, wire feeding can be challenging because aluminum wire is soft and prone to tangling. To solve this, welders often use spool guns or push–pull systems, which keep the wire feed steady and reduce bird-nesting. Spool guns are ideal for portability, while push–pull systems are better for long, continuous welds.

Aluminum Shielding Gas Selection

Shielding gas is one of the most important factors in aluminum welding because it protects the molten weld pool from contamination. The most common choice is pure argon, which provides excellent arc stability, smooth starts, and clean bead appearance. Argon works well for most TIG and MIG aluminum applications, especially on thinner materials.For thicker aluminum sections, welders often turn to argon–helium mixtures. Adding helium increases heat input, which improves penetration and weld speed. These blends are especially useful in aerospace, marine, and heavy fabrication projects. The trade-off is higher cost and a slightly more difficult arc to control.

Filler Metals for Aluminum

The choice of filler metal plays a major role in the strength, appearance, and durability of aluminum welds. Aluminum alloys respond differently to heat, so selecting the right filler ensures compatibility and reduces the risk of cracks or weak joints.

One of the most common fillers is ER4043, an aluminum-silicon rod often paired with 6xxx series alloys such as 6061. It produces smooth, attractive beads and has excellent crack resistance. For higher strength and better corrosion protection, especially in marine and structural applications, ER5356 is widely used with 5xxx series alloys.

Other fillers like ER5183 and ER5556 are chosen for heavy-duty applications such as shipbuilding, offshore structures, and pressure vessels, where maximum toughness is required. Matching the filler rod to the base alloy is critical — the wrong choice can lead to brittle welds or long-term failures. With the correct filler, welders achieve joints that balance strength, corrosion resistance, and reliability.

.

Cleaning and Surface Preparation

Aluminum is unique because it forms a thin oxide layer almost immediately when exposed to air. This oxide melts at a much higher temperature than the aluminum beneath it, making it a major barrier to clean, strong welds. Proper surface preparation is therefore one of the most critical steps before welding.The first step is mechanical cleaning, often done with a stainless steel wire brush dedicated only to aluminum. This removes the oxide layer and prevents contamination from other metals. For more thorough cleaning, chemical solutions such as acetone can be used to eliminate oils, grease, and dirt that would otherwise introduce hydrogen and create porosity in the weld. Also Surfaces should always be kept dry and clean right before welding begins

.

Heat Control and Preheating

Managing heat is one of the biggest challenges in aluminum welding. Because aluminum has high thermal conductivity, it pulls heat away from the weld zone quickly. If too little heat is applied, the weld may not penetrate properly. Too much heat, on the other hand, can lead to burn-through, warping, or loss of alloy strength. Striking the right balance is essential for strong, defect-free welds.For thick aluminum sections, preheating can make a significant difference. Bringing the material up to around 150–200°F before welding reduces thermal gradients and helps stabilize the weld pool. However, overheating must be avoided, as temperatures beyond recommended ranges can weaken the alloy and compromise corrosion resistance.

Welding Technique and Torch Movement

In TIG welding, the torch is usually held at a 10–15 degree angle, with the arc kept short for better control. The filler rod should be added steadily into the leading edge of the puddle, not directly into the arc, to avoid contamination. Smooth, consistent movement is key to preventing defects like undercut or porosity.

In MIG welding, a push technique is recommended for aluminum rather than pulling. Pushing improves shielding gas coverage and reduces soot, giving cleaner welds. Travel speed must be carefully balanced — moving too slowly can overheat the workpiece, while moving too fast can cause lack of fusion. Maintaining a steady pace, correct angle, and even filler addition ensures strong joints and a professional bead appearance.

.

Weld Quality and Inspection

Even experienced welders encounter defects in aluminum welding. Common issues include porosity, cracks, and distortion caused by poor preparation or improper technique. After welding, visual inspection is the first step, looking for surface flaws or irregular beads. For critical applications, non-destructive testing methods such as dye penetrant or X-ray inspection are used to check weld integrity. Proper inspection ensures safety, reliability, and performance, especially in industries like aerospace, automotive, and marine construction.